When You Login (Click “TAKE THIS COURSE” button) You Get Access To

- Understand the main Device Management processes.

- Understand the scope of device management based on SAP ISU

- Configure the processes related to Device Management

- Understand how Business Rules Framework is embedded into Device Management and what it can be used for

- Configure Business Rules Framework for Device Management.

- Describe how ISU/CCS is integrated with standard SAP.

- SAP ISU Device Management process improvement to include Advanced Metering Infrastructure (AMI)

- Technical data, such as register group, input/output group, and command group

- Installation as well as removal and replacement of devices in an installation

- Installation Structure for representing device and register relationships, and the rate data of these devices

- Organization and execution of meter readings in the supply area

- Device inspection: sampling procedure, certification, and periodic replacement

Device Management

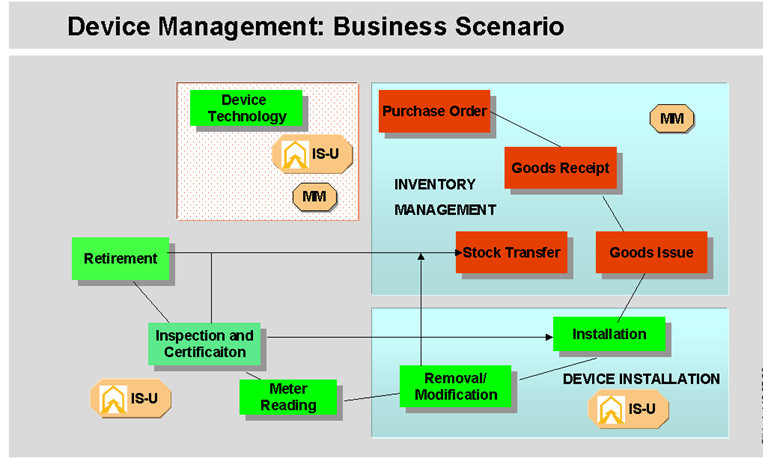

ISU/CCS Device management includes device technology , Device Installation , Meter reading and Inspection and certification of device. Device category/device is essentially identical to the material/equipment, hence all of the data and functions of the standard Logistics component are linked to Device Management module of ISU.

- Inventory Management

- Purchasing

- Warehouse management

- Plant maintenance

- Classification system

In the IS-U Device Management component, we can use IS-U-specific data and functions over and beyond the functions available in the R/3 Logistics application component. These include the following data and functions:

Course Syllabus

- Technical Master Data

- 1.1 Connection Object

- 1.2 Premise

- 1.3 Device Location

- 1.4 Installation

- Technology

- 2.1 Device

- 2.2 Device Category

- 2.3 Register Group

- 2.4 Winding Group

- 2.5 CT and PT

- 2.6 Device Life Cycle

- 2.7 Register Relationship

- Service Order

- 3.1 Installation

- 3.2 Removal

- 3.3 Replacement

- 3.4 Inspection

- Meter Reading

- 4.1 MRU and Portion

- 4.2 Schedule Records

- 4.3 Meter Reading Organization (Street Route)

- 4.4 Meter Reading Order creation

- 4.5 MRO download and Upload

- 4.6 Meter Reading Estimation

- 4.7 Meter Reading validation

- 4.8 Manual input of periodic & aperiodic meter reading

- Integration Of DM With Other Modules

- 5.1 Integration with MM

- 5.2 Integration with PM

- 5.3 Integration with EDM

- 5.4 Integration with GIS

- 5.5 Integration with AMR

Purpose of SAP Industrial Solution for Utilities (IS-U)

SAP Utilities (SAP IS-U) is a process-oriented sales and information system that supports all services of utility companies.

SAP Utilities helps to keep the business processes as streamlined and as efficient as possible. As a single software solution, SAP Utilities eliminates incompatible and isolated information in the back office.

SAP Master Data manages the data that remains fixed for long periods of time. In IS-U, this data includes the business partners, contracts and contract accounts, connection objects (buildings and real estate) and the premises, installations, and device locations contained therein.

SAP Device Management module manages the installations, meter reading scheduling and metering of all devices for the utility company

SAP IS UTILITIES COURSE COVERED.

- Utilities Industry Overview

- Introduction to SAP IS-U

- Master Data

- Business Process Documentation (BPD)

- System Configuration rationale and steps

- Functional Specification Identification and documentation.

- Training Manual Preparation

SAP IS UTILITIES COURSE CURRICULUM

| Device Management |

| Technical Device and Connection Data |

| Register Group |

| Sample Register Relationship |

| Input/Output Group |

| Command Group |

| Creating Command Groups |

| Winding Group |

| Device category |

| Device Category Creation |

| Creating Device Categories in IS-U |

| Device |

| Device Creation |

| Inspection Relevance |

| Creating Devices in Plant Maintenance |

| Creating Devices in Inventory Management |

| Device Installation |

| Device Information Record |

| Device Grouping |

| Installing, Removing or Replacing Devices |

| Device Installation |

| Device Installation |

| Device Removal |

| Device Removal |

| Device Replacement |

| Device Replacement |

| Replacement of Device Group with Another Device Gr |

| Replacement of Device Group with Smaller Device Gr |

| Replacement of Device Group with Larger Device Gro |

| Repl. of Dev. Group with Dev. Grp with Special Tec |

| Replacement of Devices in a Device Group |

| Replacement of Device Group with Complex Device |

| Replacement of Complex Device with Device Group |

| Reversal of Technical Installations, Removals and Replacements |

| Reversing Device Installations |

| Reversing Device Removals |

| Reversing Device Replacements |

| Device Modification |

| Device Modification |

| Entry of Meter Reading Results During Modification |

| Allocation of Different Device Category via MM-IM |

| Allocation of Different Device Category via PM |

| Installation Structure |

| Device Allocation |

| Creating Device Allocations |

| Rate data |

| Register Relationship |

| Period consumption |

| Logical Register Number |

| Changing Logical Register Numbers |

| Meter Reading |

| Weighting Procedure |

| Extrapolation |

| Extrapolation for Consumption Registers |

| Extrapolation for Demand Registers |

| Extrapolation for Resetting Registers |

| Extrapolation with Billing Factor |

| Proration of Meter Readings |

| Extrapolation of Demand from Billing |

| Meter Reading Organization |

| Street Route |

| Maintain Street Route for Meter Reading Unit |

| Mass Changes to Meter Reading Units |

| Meter Reading Order |

| Meter Reading Order Creation |

| Single Order Creation |

| Mass Order Creation |

| Meter Reading Control |

| Reversal |

| Order Output |

| Meter Reading Result |

| Meter Reading Result Entry |

| Independent validations |

| Dependent validations |

| Upload |

| Fast Entry With/Without Correction |

| Single Entry |

| Correction of Plausible Meter Reading Results |

| Correction of Implausible Meter Reading Results |

| Assessing |

| Estimation |

| Reversal |

| Monitoring |

| Monitoring of Meter Reading Results |

| Device Overview |

| Device Inspection |

| Sampling Procedure |

| Official/Internal Lots |

| Lot Compilation |

| Compiling Lots |

| Deleting Devices or Device Categories from Lots |

| Determination of Lot Devices |

| Drawing of Sample Devices |

| Drawing Sample Devices |

| Periodic Replacement |

| Creation of Periodic Replacement Lists |

| Work Order or Notification Creation |

| Work Order Printout |

| Certification |

| Seal Extension |

| Recording Device Inspection Data in Quality Management |

2 thoughts on “SAP ISU Device Management”

Leave a Reply Cancel reply

You must be logged in to post a comment.

Good evening.

I would like to know if this course still available, please?

Yes it is available. You can click and register