CIE AS/A Level Physics 6.2 Elastic and plastic behavior Study Notes- 2025-2027 Syllabus

CIE AS/A Level Physics 6.2 Elastic and plastic behavior Study Notes – New Syllabus

CIE AS/A Level Physics 6.2 Elastic and plastic behavior Study Notes at IITian Academy focus on specific topic and type of questions asked in actual exam. Study Notes focus on AS/A Level Physics Study Notes syllabus with Candidates should be able to:

- understand and use the terms elastic deformation, plastic deformation and elastic limit

- understand that the area under the force–extension graph represents the work done

- determine the elastic potential energy of a material deformed within its limit of proportionality from the area under the force–extension graph

- recall and use \(E_p=\frac{1}{2}F\times x=\frac{1}{2}kx^2\)for a material deformed within its limit of proportionality

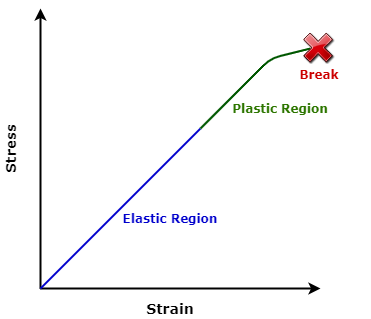

Elastic and Plastic Deformation

When a material is subjected to a force, it changes shape or length. The nature of this deformation depends on the magnitude of the force and the material’s properties.

Elastic Deformation

Elastic deformation is the temporary deformation of a material where it returns to its original shape and dimensions once the applied force is removed.

Characteristics:

- Occurs when the applied stress is within the material’s elastic limit.

- The extension (or strain) is directly proportional to the applied force (obeying Hooke’s Law): \( \mathrm{F \propto \Delta L} \) or \( \mathrm{F = k\Delta L.} \)

- The deformation is completely reversible — the material regains its original length when the force is removed.

- Examples: stretching of a spring, bending of a ruler slightly.

Plastic Deformation

Plastic deformation is the permanent deformation of a material where it does not return to its original shape after the deforming force is removed.

Characteristics:

- Occurs when the applied stress exceeds the elastic limit of the material.

- Atoms or molecules within the material move to new equilibrium positions — permanent rearrangement occurs.

- The material may still stretch further, but the deformation becomes irreversible.

- Examples: permanent bending of a metal wire, denting of a car panel.

Elastic Limit

The elastic limit is the maximum stress or force that can be applied to a material without causing permanent (plastic) deformation.

- Below the elastic limit → deformation is elastic.

- Beyond the elastic limit → deformation becomes plastic.

- Once the elastic limit is crossed, the material will not return to its original shape even if the load is removed.

Graphical Representation

When the extension of a material (like a spring or wire) is plotted against the applied force, a force–extension graph is obtained.

- The initial straight-line portion represents elastic deformation (Hooke’s Law region).

- The point where the line begins to curve marks the limit of proportionality.

- Beyond this point, the material eventually reaches the elastic limit.

- Further increase in force leads to plastic deformation — permanent extension occurs.

Example

A copper wire is stretched and the following observations are made: (i) It extends 2 mm under a 10 N force and returns to its original length when unloaded. (ii) Under a 15 N force, it extends 4 mm but remains 1 mm longer after the force is removed. Identify the type of deformation in each case.

▶️ Answer / Explanation

(i) The wire returns to its original length → Elastic deformation.

(ii) The wire does not return fully → Plastic deformation has occurred.

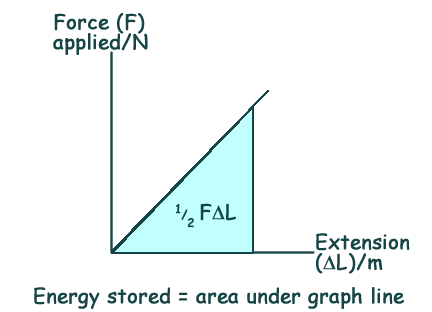

Work Done and the Area Under a Force–Extension Graph

The work done in stretching a material (such as a spring or wire) is equal to the area under its force–extension graph.

\( \mathrm{W = \text{Area under the } F\text{–}\Delta L \text{ graph}} \)

For a Linear (Elastic) Region:

Since \( \mathrm{F = k\Delta L} \), the graph is a straight line through the origin.

The area under the line is a triangle with base \( \mathrm{\Delta L} \) and height \( \mathrm{F.} \)

\( \mathrm{W = \tfrac{1}{2}F\Delta L = \tfrac{1}{2}k(\Delta L)^2.} \)

- Work done = elastic potential energy stored in the spring or wire.

- When the force is removed (within elastic limit), this energy is released — the material returns to its original shape.

For a Non-linear (Plastic) Region:

- The area under the curve (can be irregular) represents total work done — some of which is stored as elastic energy, and the rest is dissipated as heat due to internal molecular rearrangements.

- Hence, only part of the energy is recoverable once plastic deformation begins.

Example

A spring obeying Hooke’s Law is extended by \( \mathrm{0.10\,m} \) when a force of \( \mathrm{20\,N} \) is applied. Calculate the elastic potential energy stored in the spring.

▶️ Answer / Explanation

From Hooke’s Law: \( \mathrm{F = k\Delta L \Rightarrow k = \dfrac{F}{\Delta L} = \dfrac{20}{0.10} = 200\,N/m.} \)

Work done (energy stored): \( \mathrm{E = \tfrac{1}{2}k(\Delta L)^2.} \)

\( \mathrm{E = \tfrac{1}{2}(200)(0.10)^2 = 1.0\,J.} \)

The spring stores \( \mathrm{1.0\,J} \) of elastic potential energy.

Elastic Potential Energy and the Force–Extension Graph

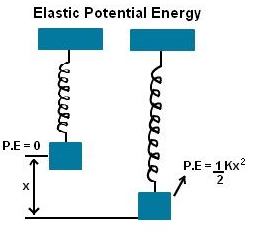

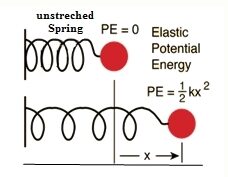

When a material such as a spring or wire is stretched within its limit of proportionality, it stores elastic potential energy — the energy associated with its deformation.

Origin of Elastic Potential Energy:

- As work is done to stretch the material, the applied force displaces atoms slightly from their equilibrium positions.

- When the deforming force is removed (and the deformation is elastic), this energy is released as the material returns to its original shape.

- This energy is the area under the force–extension graph in the linear (Hookean) region.

Graphical Representation:

- For a material obeying Hooke’s Law, the graph of \( \mathrm{F} \) vs \( \mathrm{x} \) (extension) is a straight line through the origin.

- The area under the straight line represents the work done in stretching the material — i.e. the elastic potential energy stored.

\( \mathrm{E_p = \text{Area under } F \text{–} x \text{ graph}} \)

For a linear (triangular) graph:

\( \mathrm{E_p = \tfrac{1}{2} \times F \times x.} \)

Key Concept:

The limit of proportionality is the point up to which Hooke’s Law holds — i.e., force is directly proportional to extension (\( \mathrm{F \propto x} \)). Beyond this limit, the graph curves, and the stored energy is no longer fully recoverable.

Example

A spring is stretched by \( \mathrm{0.20\,m} \) under a force of \( \mathrm{10\,N.} \) Assuming it obeys Hooke’s Law, determine the elastic potential energy stored in the spring.

▶️ Answer / Explanation

For a linear (Hookean) spring, the area under the \( \mathrm{F\text{–}x} \) graph = triangle area.

\( \mathrm{E_p = \tfrac{1}{2}F x = \tfrac{1}{2}(10)(0.20) = 1.0\,J.} \)

The elastic potential energy stored in the spring is \( \mathrm{1.0\,J.} \)

Derivation of the Formula ( \mathrm{E_p = \tfrac{1}{2}F x = \tfrac{1}{2}k x^2}\)

Starting Point:

From Hooke’s Law: \( \mathrm{F = kx.} \)

Elastic potential energy = work done to stretch the spring:

\( \mathrm{E_p = \int_0^x F\,dx.} \)

Substitute \( \mathrm{F = kx.} \):

\( \mathrm{E_p = \int_0^x kx\,dx = k\int_0^x x\,dx = \tfrac{1}{2}kx^2.} \)

Hence,

\( \mathrm{E_p = \tfrac{1}{2}k x^2.} \)

Alternative Expression (Using Final Force):

Since \( \mathrm{F = kx,} \) then \( \mathrm{k = \dfrac{F}{x}.} \)

Substitute into \( \mathrm{E_p = \tfrac{1}{2}k x^2:} \)

\( \mathrm{E_p = \tfrac{1}{2} \dfrac{F}{x}x^2 = \tfrac{1}{2}F x.} \)

Therefore, the two equivalent forms are:

- \( \mathrm{E_p = \tfrac{1}{2}F x} \)

- \( \mathrm{E_p = \tfrac{1}{2}k x^2} \)

Physical Meaning:

- \( \mathrm{E_p} \): Elastic potential energy stored (J)

- \( \mathrm{F} \): Final force applied (N)

- \( \mathrm{k} \): Spring constant (N·m⁻¹)

- \( \mathrm{x} \): Extension or compression (m)

Interpretation:

- The energy stored increases with the square of the extension.

- Doubling the extension increases the energy by four times.

- This energy is recoverable only if the spring is not stretched beyond its proportional limit.

Example

A spring has a spring constant of \( \mathrm{200\,N·m^{-1}}. \) Find the elastic potential energy stored when the spring is stretched by \( \mathrm{0.15\,m.} \)

▶️ Answer / Explanation

Using \( \mathrm{E_p = \tfrac{1}{2}k x^2} \):

\( \mathrm{E_p = \tfrac{1}{2}(200)(0.15)^2 = 100 \times 0.0225 = 2.25\,J.} \)

The elastic potential energy stored = \( \mathrm{2.25\,J.} \)

Example

A spring extends by \( \mathrm{0.25\,m} \) under a load of \( \mathrm{8.0\,N.} \) Calculate the elastic potential energy stored using both formulas and confirm they give the same result.

▶️ Answer / Explanation

From Hooke’s Law: \( \mathrm{k = \dfrac{F}{x} = \dfrac{8.0}{0.25} = 32\,N·m^{-1}.} \)

Using \( \mathrm{E_p = \tfrac{1}{2}F x:} \)

\( \mathrm{E_p = \tfrac{1}{2}(8.0)(0.25) = 1.0\,J.} \)

Using \( \mathrm{E_p = \tfrac{1}{2}k x^2:} \)

\( \mathrm{E_p = \tfrac{1}{2}(32)(0.25)^2 = 16 \times 0.0625 = 1.0\,J.} \)

Both methods give \( \mathrm{E_p = 1.0\,J.} \), confirming consistency.