Proportionality limit and Yield strength

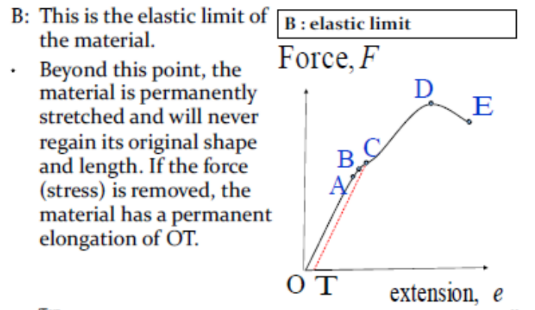

• Proportionality limit and Elastic limit Maximum amount a material can be stretched by a force and still (or may) return to its original shape depends on the material.

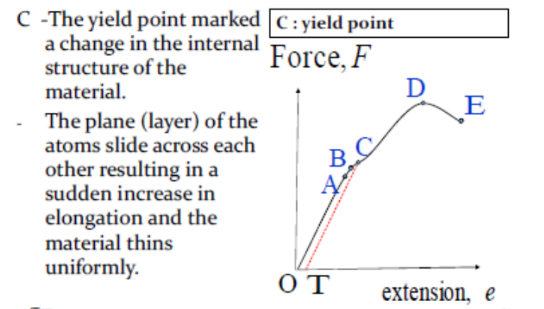

• Yield point or Yield strength The point where there is a large permanent change in length with no extra load force. yield point :- interface between elasticity and plasticity

- Elastic limit – up to which material can sustain the load and return back to its original position.

- Although these two points are so close to each other it can be treated as one, on a case to case basis.

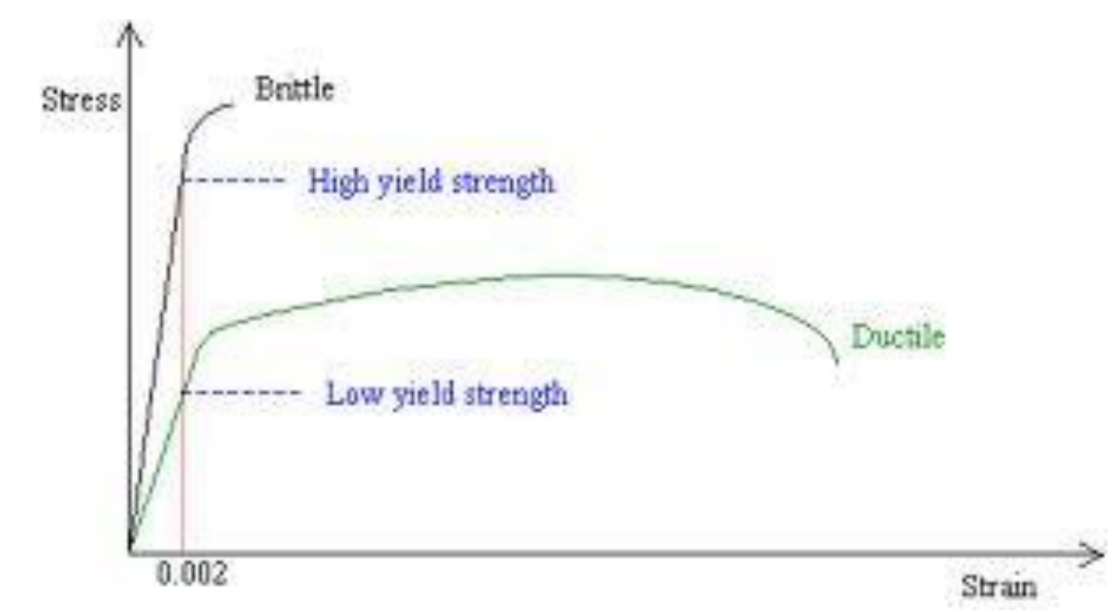

- It depends upon material whether it’s brittle or ductile.

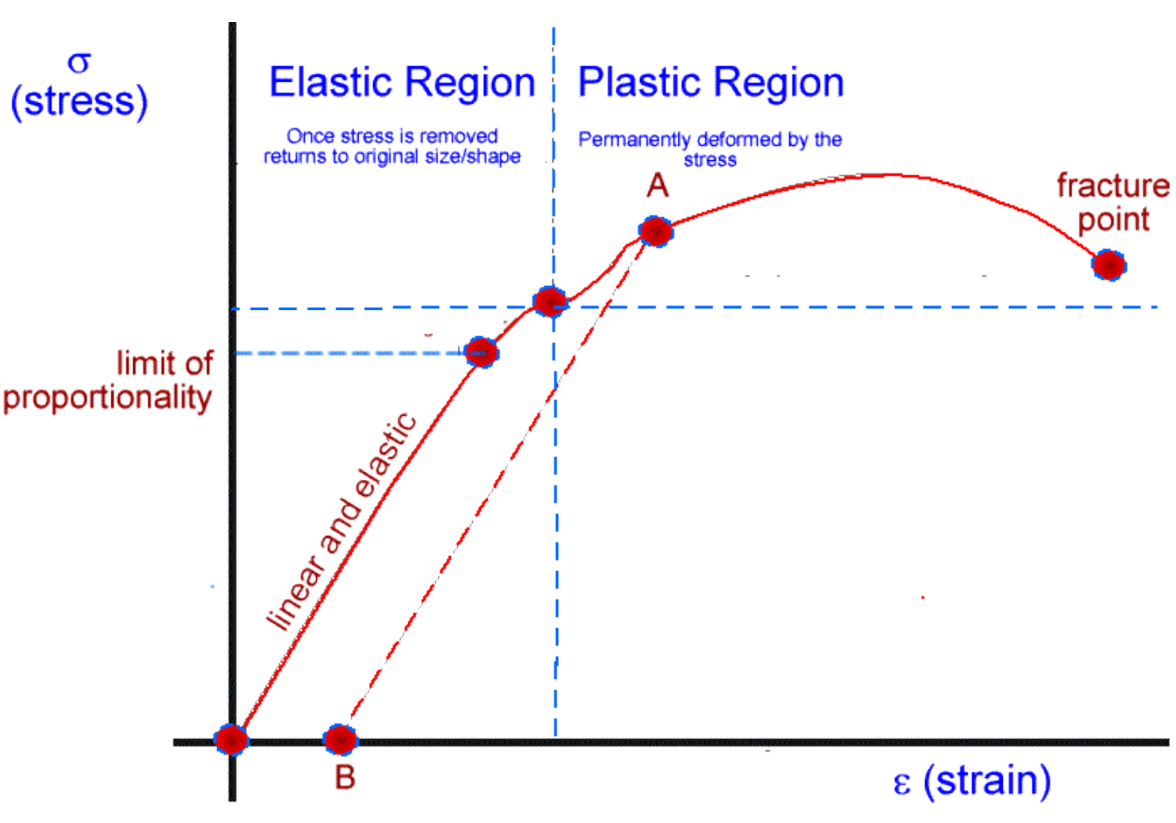

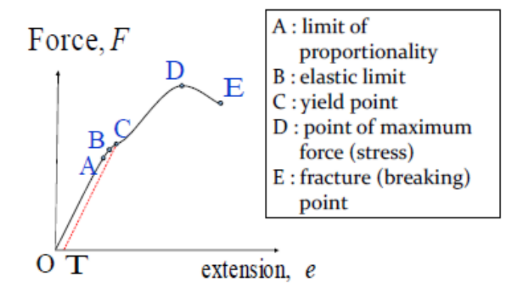

Explaining Graph in the previous slide…..

- The stretching behavior is summarized in a stress-strain graph in the previous slide. As the stress is increased initially Hooke’s Law is obeyed – the stress-strain relationship for the wire is linear \& elastic.

- Just before the plastic region is reached we get the limit of proportionality – beyond this for a small section we see non-linear behaviour but the stretching is still elastic.

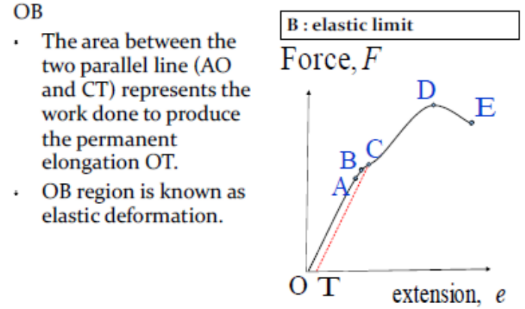

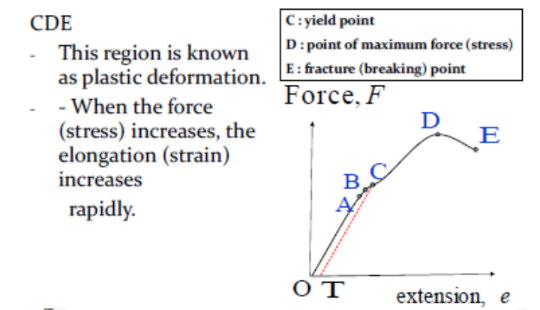

- After the yield strength, the material enters the plastic deformation region, which means that the stretch of the wire is permanent. (For example, if the wire is stressed to point $A$ on the graph and the stress is slowly decreased, the stress-strain curve follows the dotted line instead of the original curve to point $\mathbf{B}$ and there is a permanent extention when all stress is removed.) At the facture point the wire snaps.

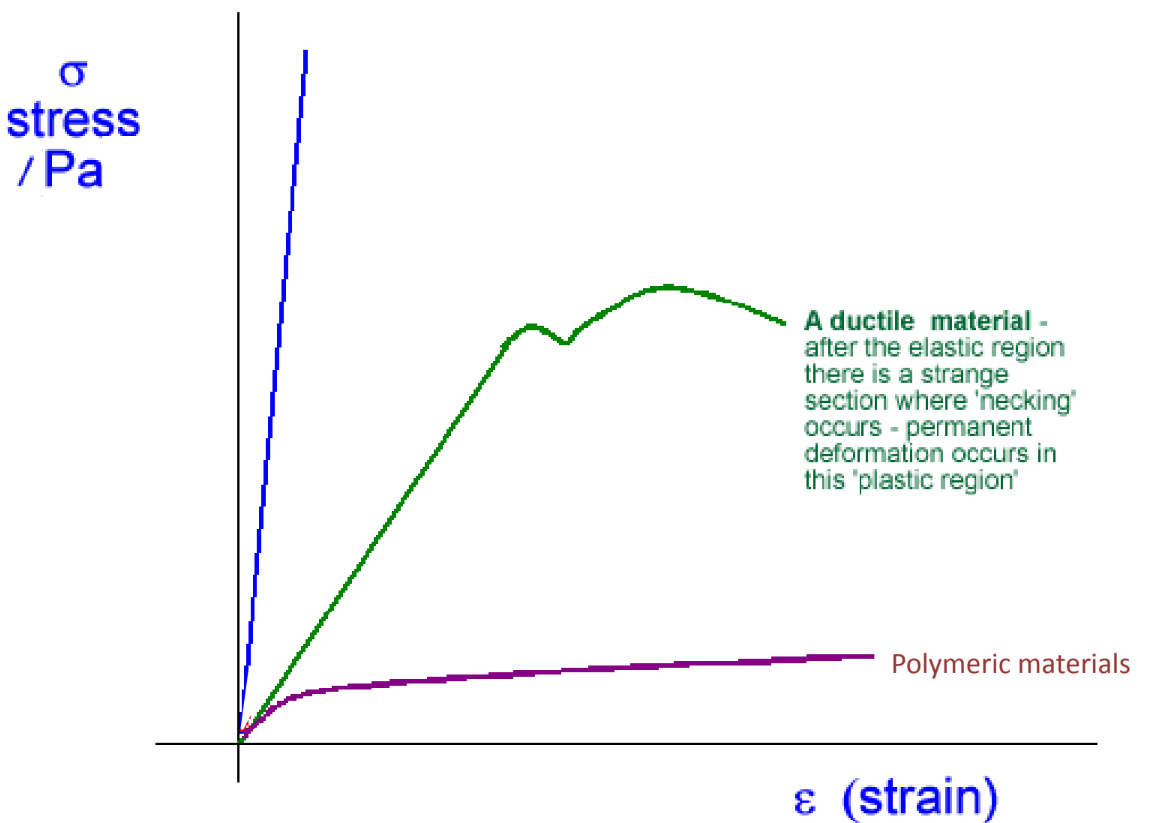

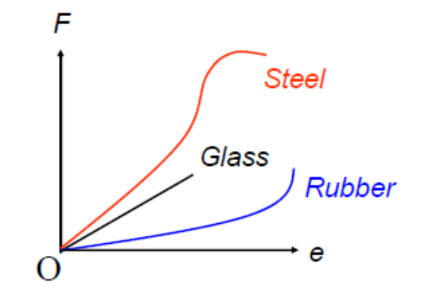

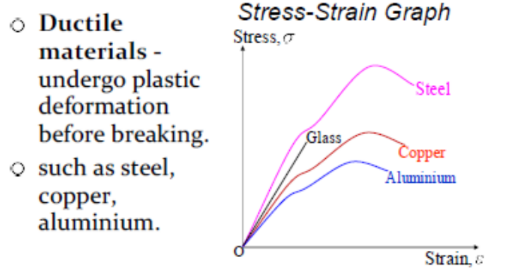

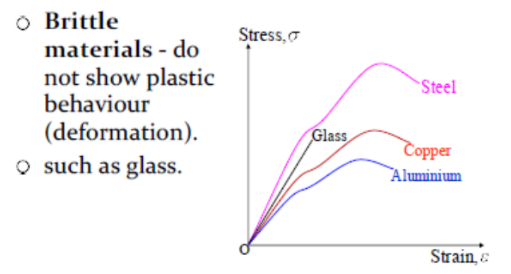

- Differences in the shape and limits of the stress-strain diagram determines whether a material is considered ductile or brittle, elastic or plastic.

A brittle material. This material is also strong because there is little strain for a high stress. The fracture of a brittle material is sudden with little or no plastic deformation.. Glass is brittle

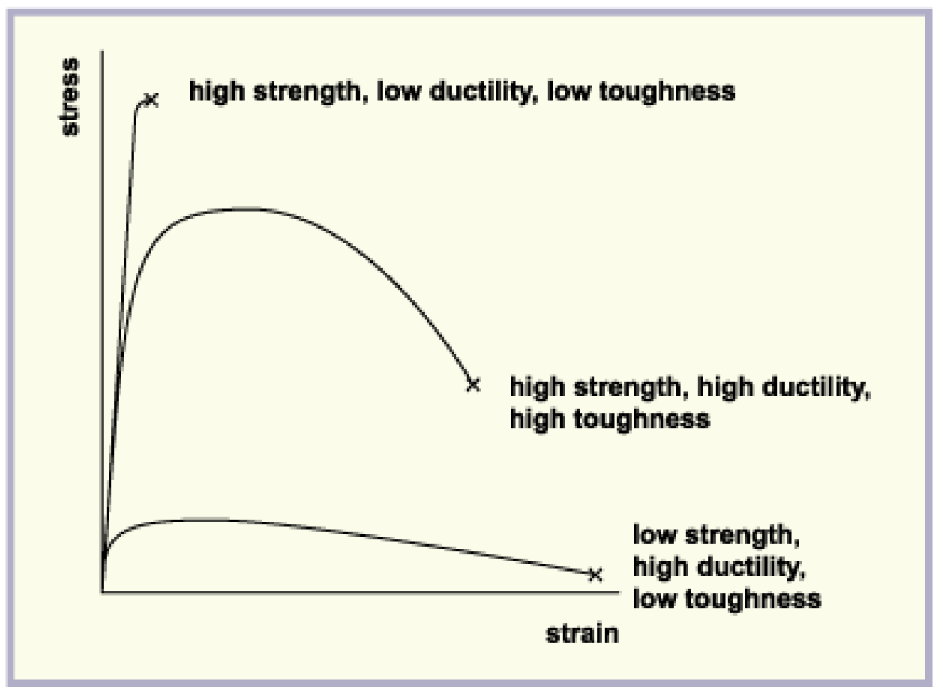

Strength, Ductility & Toughness

High Yield strength & Low yield strength

Energy in deformations

- Whenever we apply force to an object, it will cause deformation. If the deformation caused is within the elastic limit, the work done in deforming the object is stored within it as potential energy. We call this (elastic) ‘strain energy’. It can be released from the object by removing the applied force.

- The strain energy then performs work in undeforming the object and returns to its original state.

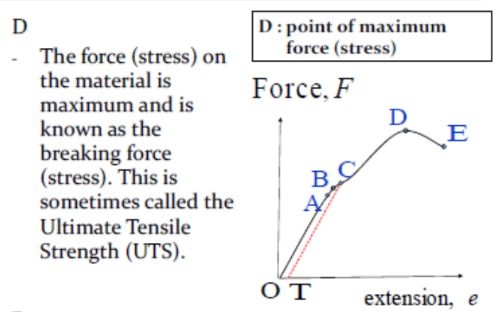

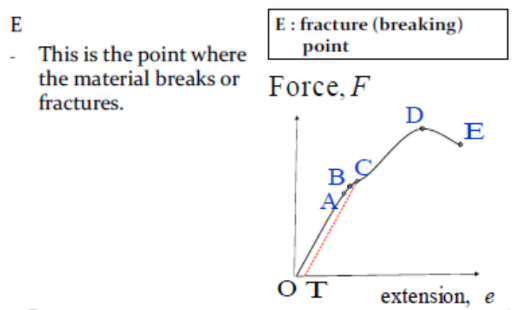

Force-extension graphs for typical ductile, brittle and polymeric materials, including an understanding of ultimate tensile stress.

Force-Extension Graphs

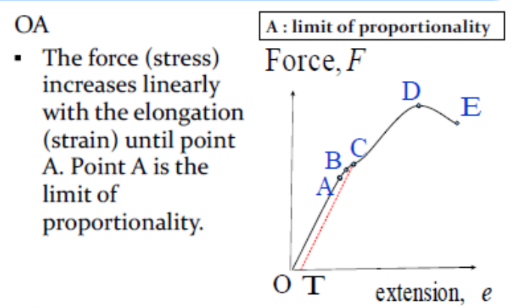

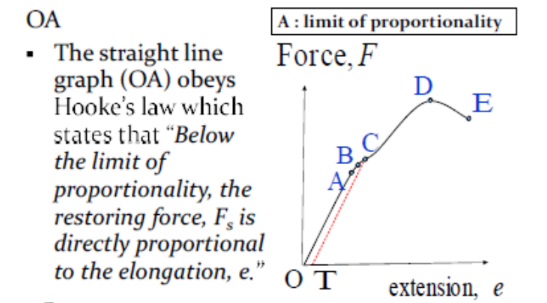

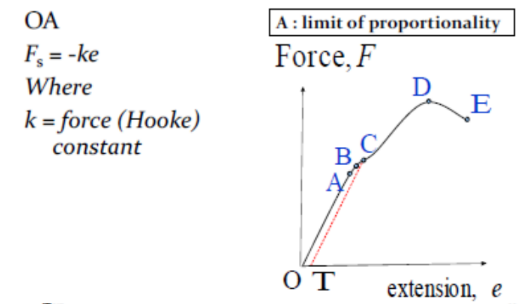

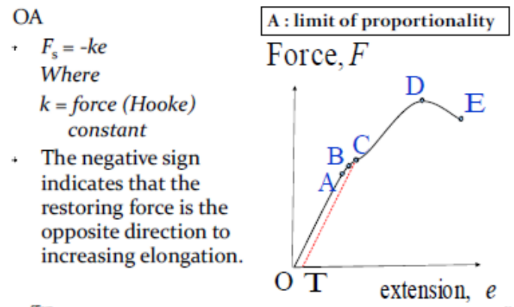

$\mathrm{OA}$

- The straight line graph (OA) obeys Hooke’s law which states that “Below the limit of proportionality, the restoring force, $F_s$ is directly proportional to the elongation, e.”

Force-Extension Graphs and Stress-Strain Graph

A : limit of proportionality

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Force-Extension Graphs

Extension-Force Graphs

Types of materials

Types of materials

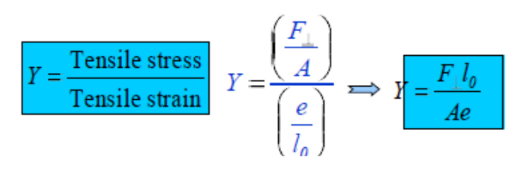

Young’s Modulus ( $Y @ E$ )

- Definition – is defined as the ratio of the tensile stress to the tensile strain if the limit of proportionality has not been exceeded.

Young’s Modulus ( $Y @ E$ )

- Its dimension is given by

$

[Y]=\frac{\left[F_{\perp}\right]\left[l_0\right]}{[A] e]}=M L^{-1} T^{-2}

$

The unit of Young’s modulus is $\mathrm{kg} \mathrm{m}^{-1} \mathrm{~s}^{-2} @ \mathrm{~N} \mathrm{~m} \mathrm{~m}^{-2} @ \mathrm{~Pa}$.