Edexcel A Level (IAL) Biology -4.9 Core Practical 8: Determining the Tensile Strength of Plant Fibres- Study Notes- New Syllabus

Edexcel A Level (IAL) Biology -4.9 Core Practical 8: Determining the Tensile Strength of Plant Fibres- Study Notes- New syllabus

Edexcel A Level (IAL) Biology -4.9 Core Practical 8: Determining the Tensile Strength of Plant Fibres- Study Notes -Edexcel A level Biology – per latest Syllabus.

Key Concepts:

- 4.9 Determine the tensile strength of plant fibres.

CORE PRACTICAL 8 – Determining the Tensile Strength of Plant Fibres

🌱 Aim

To compare the tensile strength (ability to resist breaking when stretched) of different plant fibres such as flax, jute, and hemp.

🔬 Introduction

Tensile strength means how much force a fibre can take before it breaks.

Plant fibres like xylem and sclerenchyma provide strength and support to plants.

These natural fibres can be used to make biodegradable ropes, fabrics, and composites a sustainable alternative to plastics.

Key Idea:

Strong plant fibres = better structural materials for sustainable use

- Thicker and longer fibres have higher strength.

- More cellulose and lignin → greater rigidity.

- Wet fibres are weaker because water breaks hydrogen bonds.

⚙️ Apparatus

- Plant fibres (flax, jute, hemp etc.)

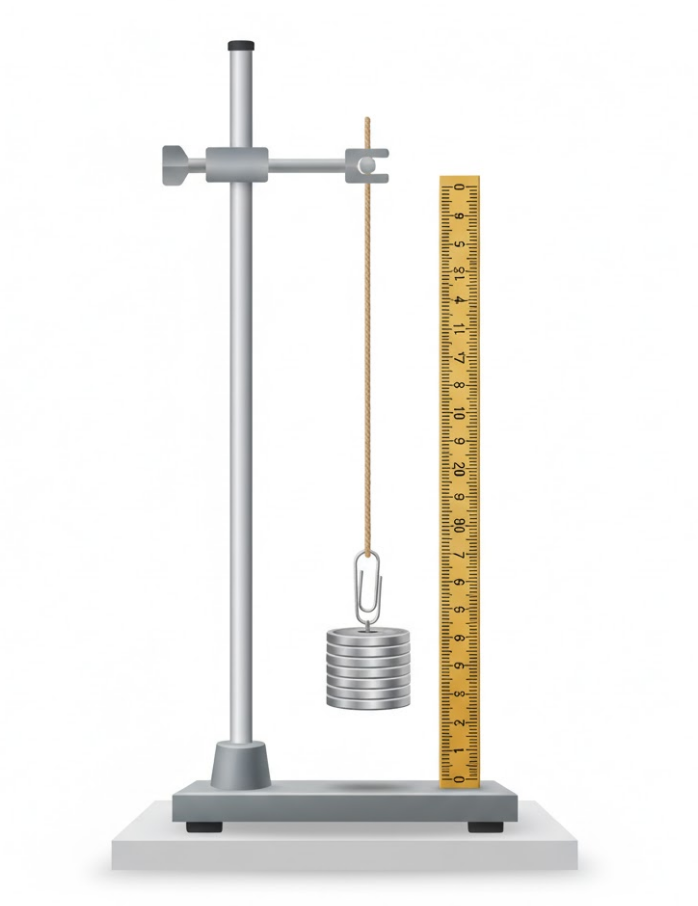

Clamp stand

Clamp stand- Weights or force gauge

- Ruler or meter scale

- Micrometer (optional, for measuring diameter)

- Stopwatch (if applying weights gradually)

- Paper clips or bulldog clips

🧫 Procedure (Step-by-Step)

- Prepare fibres: Cut equal-length strands of each fibre type.

- Soak (optional): If testing both dry and wet fibres, soak some in water for 30 minutes.

- Set up: Fix one end of the fibre to a clamp stand using clips.

- Add weights: Hang weights gradually until the fibre breaks.

- Record force: Note the maximum load (in newtons) before snapping.

- Repeat: Perform at least 3 trials per fibre type and calculate the average load.

📊 Calculations

Tensile Strength (Pa) = Force at break (N) ÷ Cross-sectional area (m²)

If the cross-sectional area cannot be measured, simply compare the force (N) at which fibres break.

📈 Example Results Table

| Fibre Type | Length (cm) | Max Load (N) | Average Load (N) | Relative Strength |

|---|---|---|---|---|

| Flax | 10 | 2.8 | 2.7 | High |

| Jute | 10 | 2.1 | 2.0 | Medium |

| Hemp | 10 | 3.2 | 3.3 | Very High |

🎯 Conclusion

- Fibres with more cellulose and lignin have higher tensile strength.

- Dry fibres are stronger than wet fibres.

- Natural fibres show potential for eco-friendly industrial use.

⚠️ Precautions

- Keep fibre lengths constant.

- Add weights slowly to avoid jerks.

- Avoid knots or uneven fibres.

- Repeat tests to ensure reliable averages.

📦 Quick Recap

| Key Term | Meaning |

|---|---|

| Tensile strength | Resistance to breaking when pulled or stretched |

| Lignin | Rigid, waterproof polymer giving extra strength |

| Cellulose | Main structural polysaccharide in plant cell walls |

| Dry fibre | Stronger because hydrogen bonds remain intact |

| Wet fibre | Weaker as water disrupts H-bonds |

| Sustainable use | Plant fibres can replace synthetic plastics |